What do many people think of when they imagine a shift change at a factory? Unless they work inside one, they may think of the assembly line of Henry Ford’s day. But within the industry, vast changes in technology and global trade have transformed the way we design and produce things.

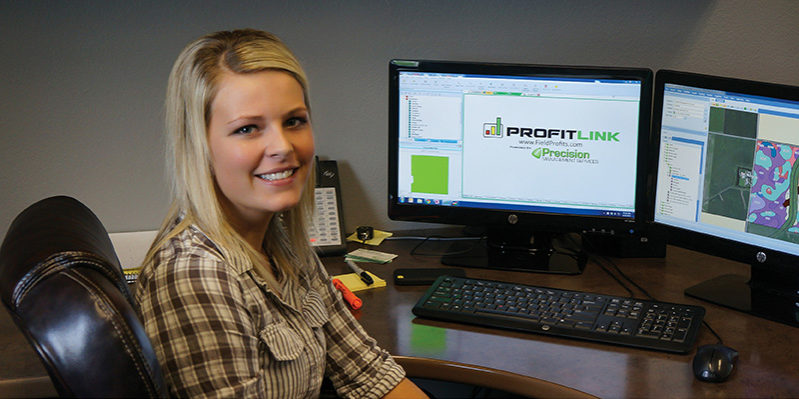

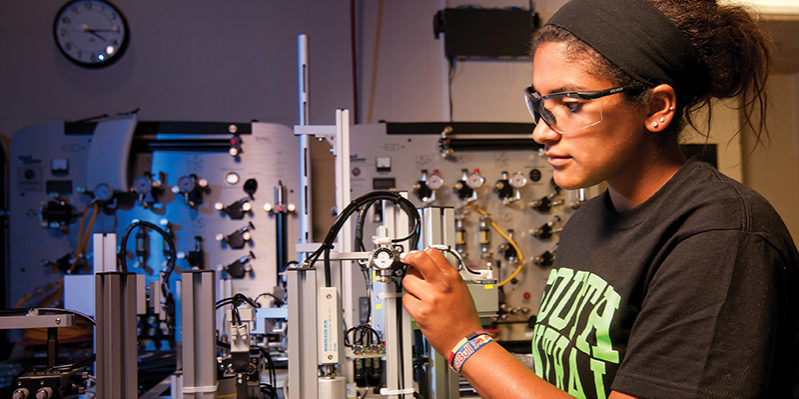

We live in the era of Advanced Manufacturing, where workers with a high level of technical skills are needed to run and maintain complex machines, robots and computer systems. Far from the negative stereotypes of manufacturing, most of the new jobs in industry are clean, steady and offer good pay.

In fact, manufacturing workers are some of the best paid workers in the country, says AJ Jorgenson of the Manufacturing Institute. “Today’s manufacturing employees earn higher wages and receive more generous benefits than other working Americans.” Jorgenson noted that for 2013, with average wages and benefits totaling $33.93 per hour, “There is almost a 9 percent premium for working in manufacturing.”

Demand for Skilled Workers Skyrocketing

Fields like Computer Integrated Machining, Mechatronics and Welding are booming.

According to the U.S. Department of Labor, Advanced Manufacturing occupations grew by 99.4 percent between 2007 and 2012. And since 2013, America’s advanced industries have continued to expand faster than the overall economy, adding thousands of high-skill jobs and billions of dollars to the national gross domestic product, according to a 2016 analysis by the Brookings Institution. As the Baby Boom generation retires, demand for new manufacturing workers will only continue to grow. Currently, Baby Boomers make up about 20 percent of the overall workforce and an even larger share of industrial jobs.

Turning the Tide of Perception

However, public perception remains a struggle, says Rob Sentz, chief innovation officer at Economic Modeling Specialists International (EMSI), who says he’s seen parents advising their children against pursuing a career in manufacturing. This has contributed to what employers call a ‘skills gap,’ with too few technical workers filling too many jobs. According to the Manufacturing Institute’s Jorgenson, “80 percent of manufacturers report they cannot find individuals with the skills required.”

Manufacturing Transformation

American manufacturing is leaner and far more productive than the factories of old. In fact, the Manufacturing Institute reports that in the two decades up to 2012, manufacturing output increased more than 83 percent.

If the U.S. manufacturing sector were its own country all on its own, it would still rank as the eighth largest economy in the world – producing more than the entire gross domestic product of India, a well-known export giant!

Manufacturing in America is leaner and smarter today. This means that the jobs that “return” to the U.S. are different than those that left in the past several decades. They are more technical and 80 percent require some training, according to a 2012 study by Georgetown University’s Public Policy Institute.

“Today’s manufacturing is about advanced technologies, state-of-the-art facilities and fast-paced work environments,” states Jorgenson. “It’s where the thought becomes the thing.”

ADVANCED MANUFACTURING

Are you the type of person who likes to figure out how things work? Do you like to create new things and perhaps figure out how to make existing products better? Then a career in Advanced Manufacturing may be for you.

|

Programs |

MN Median |

Minnesota |

Potential Career Paths |

|

Computer Integrated Machining |

$22.10 |

$45,968 |

Machinist CNC Machine Tool Programmer |

|

Energy Technical Specialist |

$28.18 |

$58,614 |

Energy Technician |

|

Mechatronics |

$27.40 |

$56,992 |

Industrial Machine Mechanic |

|

Welding |

$19.00 |

$39,520 |

Welder/Solderer Cutter/Brazer |

*Starting salaries may be lower and more experience can demand higher levels of pay.

Source: Economic Modeling Specialists International (EMSI)